The pilot plant for smart maintenance

Prevent downtime. With Edge AI and TinyML, predictive maintenance becomes feasible, affordable and effective for manufacturing SMEs. Smart sensors and microcontrollers analyse data directly on the machines; real-time, without cloud or delay. So you can immediately see what is happening and what is coming up.

The result? Fewer failures, lower costs, higher yields and more control over energy and maintenance. At the Fieldlab Edge AI, we help you put this technology into practice. We do this from our own Smart Sensor Lab, among other places.

why edge ai?

The manufacturing and maintenance industry in the IJmond region emits too much CO₂ and wastes too much energy. In order to remain competitive and independent, also internationally, as well as maintaining our licence to operate, something has to change in the manufacturing industry.

It starts with insight; knowing exactly how much energy you currently consume in production, what the condition of your assets is. Then you can get a grip on energy consumption and emissions, and discover where the profit lies. In this way, it is possible to produce cheaper and faster.

Lower costs , higher yield, real-time insight into condition monitoring, low data traffic and cloud storage as well as more security and privacy control. The benefits speak for themselves.

With Edge AI, predictive maintenance becomes a reality.

edge ai & tiny ml for predictive smart maintenance

Smart sensors, real-time data and Edge AI such as Tiny Machine Learning models run directly on the machines in the factory, on energy-efficient microcontrollers. This allows you to see live what is happening, without delay or cloud costs. Predictions take place right there 'on the edge', i.e. on the machine itself. TinyML is low-threshold, affordable and perfect for SMEs. You get faster insights, save costs and lower your carbon footprint.

At Fieldlab Edge AI for Smart Industry, we help you implement this technology step by step. This is how we make industry smarter, more sustainable and ready for the future

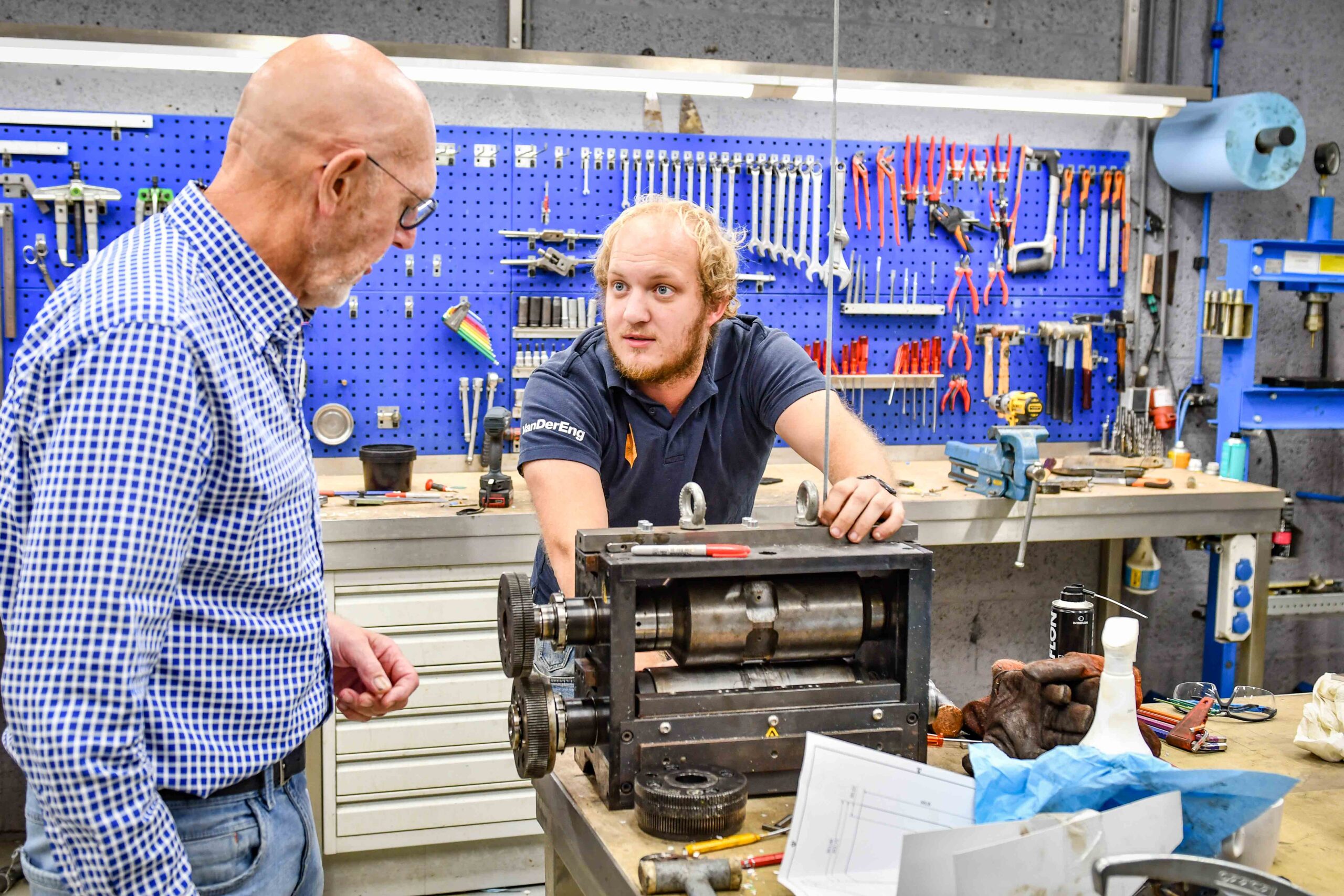

visit the smart sensor lab

Innovation in the manufacturing industry does not happen by itself. That is why there is the Smart Sensor Lab: a hands-on lab where you as an SME can experiment with smart technology such as Edge AI, Tiny Machine Learning, sensor technology and real-time data analysis.

Here, you work together with students, researchers and technicians on concrete applications that really make a difference.

Predictions take place directly "on the edge", or on the machine itself.

André Gerver - Project manager

more information and/or register?

At Fieldlab Edge AI for Smart Industry, we help you implement this technology step by step. This is how we make industry smarter, more sustainable and ready for the future.

Ready for take-off?

For all information on the Fieldlab Edge AI for Smart Industry, contact us at fieldlab@techport.nl. We will get back to you as soon as possible.

Contact

fieldlab@techport.nl | 📱 06 - 18 84 73 00