Smart machines without expensive IT:

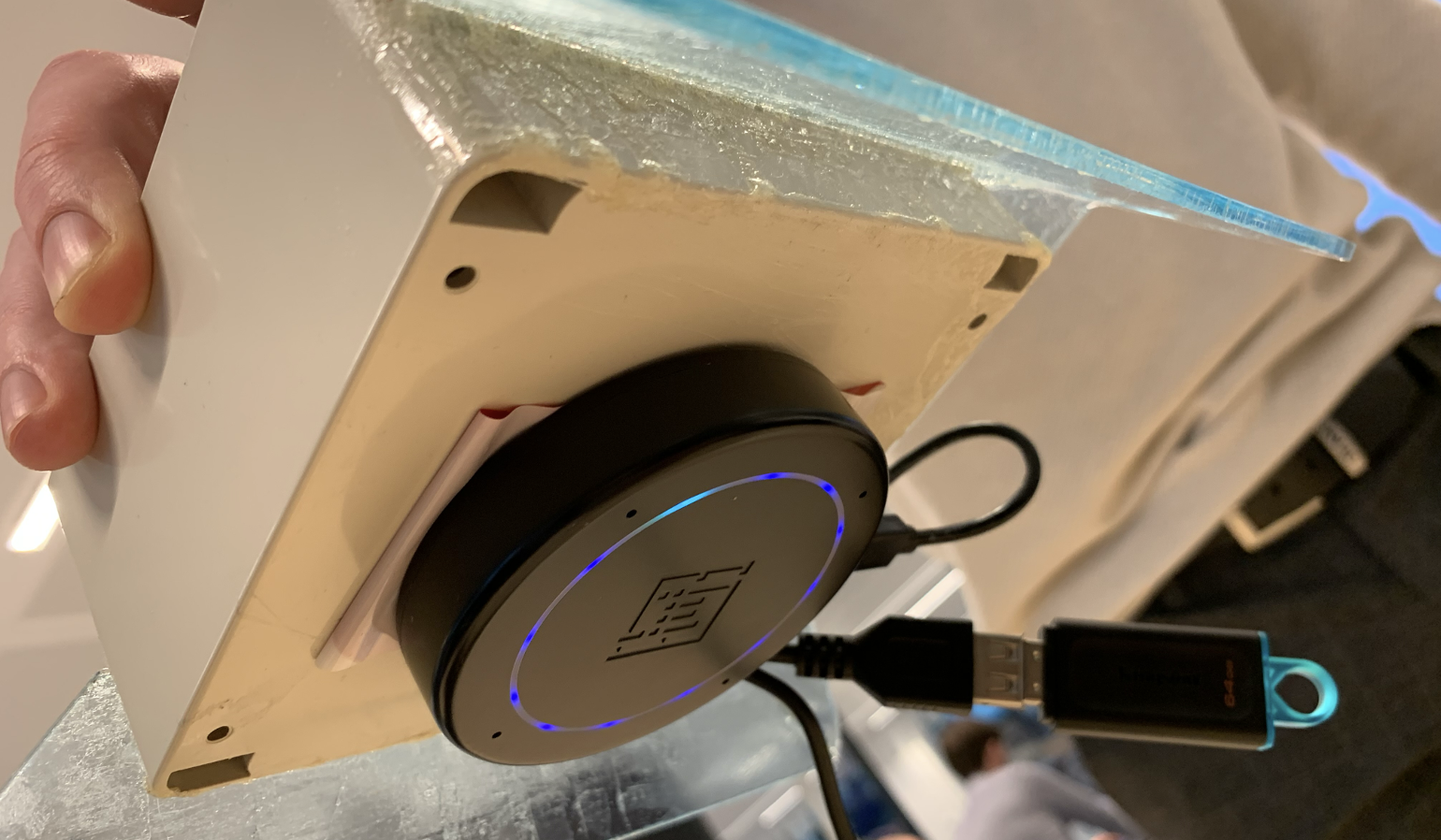

This is how Edge Ai works

Machines produce valuable data every day, only nobody does anything with it. And that while smart technology such as Edge AI and TinyML identify faults, predict maintenance and optimise energy consumption, without complicated IT or expensive cloud systems.

Three ways TinyML makes your maintenance smarter

Maintenance no longer has to be about putting out fires. Thanks to TinyML, you can let machines predict when something is about to go wrong. And that without expensive software or complex cloud platforms. TinyML runs on small chips that you put directly on your machine. They analyse data in real time and give a signal before things go wrong. In this blog, you will read about three ways SMEs in the manufacturing industry can start using it today.

From downtime to predictable; this is how predictive maintenance works

In many manufacturing companies, maintenance is still reactive: you only intervene when something breaks down. But every breakdown means downtime, costs and frustration. Predictive maintenance takes a different approach. By continuously monitoring machines with smart sensors and real-time data analysis, you see problems coming before they happen. You prevent breakdowns and extend the life of your equipment.

AI is too expensive and complex for SMEs: Fact or fable?

AI is for big companies hefty budgets and their own data team. Right? In practice, we see the opposite. It is precisely in SMEs that there are great opportunities. Not with heavy cloud solutions or complicated models, but with smart, lightweight technology that you apply directly on the shop floor, such as Edge AI and TinyML. You can read how that works in this article.

This is how edge ai makes your factory greener

The manufacturing industry is under pressure to produce more sustainably. Energy prices are rising, raw materials are becoming scarcer and laws and regulations are becoming stricter. Edge AI can help accelerate this transition. Not through large investments or complicated systems, but by deploying smart technology directly on the shop floor.

Smarter manufacturing starts here: 5 opportunities you can seize now

Many manufacturing SMEs want to work smarter and more sustainably, but do not always know where to start. Smart technologies like Edge AI and TinyML are affordable and practically applicable. They not only help you improve processes, but also reduce costs and increase quality. In this blog, you will read more about five concrete opportunities you can seize now.

getting started with smart manufacturing

With Smart Manufacturing, you make a production process smarter through technology. Think sensors that measure deviations, algorithms that predict maintenance or data that give real-time insight. In short: direct applications that make your factory more efficient, sustainable and profitable. You can read how to start such a transition in this blog.