New technology offers IJmond students inside knowledge of predictive maintenance

Interview Daisy Beelen:

'Students get to work with this wonderful system!'

In recent months, Nova College has had a thorough renovation done at Techport's Smart Maintenance field lab located near the Tata Steel Academy. These renovations offer great opportunities for the technical oneducation and engineering companies.As of now, the pilot plant can be remotely be used for education. With this new technology, students at Nova College may learn the methods of the future. Perform maintenance as quickly and effectively as possible, saving resources and energy.

Techport's pilot plant will be used for students from the Tata Steel Academy and Nova College in the coming years, and perhaps other schools in the future. The students follow various technical courses such as process engineering, mechanical engineering, electrical engineering and ICT. The first practical assignments are ready and students from the process engineering course will soon be allowed to work with the pilot installation. Daisy Beelen, Practor Circular entrepreneurship & Smart maintenance and lecturer Process Engineering Nova College: "These students are the frontrunners! They may be the first to work with this wonderful system. Then we will implement it in phases at the other courses. By installing vibration meters and sound sensors, for example, they can read out various data remotely and learn to analyze this big data in order, for example, to adjust maintenance plans accordingly. With this new technology, they are already gaining solid prior knowledge with which they can act on the job market."

Remote maintenance prediction of machines with the whole class

The biggest advantage of this new technology is that students can now really experience it in practice. The entire class can operate and read the system remotely. The data comes in on the dashboard and with this information students can predict machine maintenance. Teachers from Nova College and coaches from the Tatasteel Academy have already had a trial run and they are very enthusiastic. Marcel Dam, Manager Vocational Training Tata Steel Academy: "We have waited a long time for this! Now we can integrate installation within the curriculum of our vocational courses. It is a different way of interpreting your installations. We have wanted this development for years and it is incredibly nice that it is now possible!"

Broad approach to integrating technology in education

The Nova College is in talks with several educational institutions. Including Jurjen Helmus of the Smart lab of Hogeschool van Amsterdam to use the field lab in a collaboration between MBO and HBO students. But there are also discussions going on with Inholland in the field of Tiny Machine Learning. André Gerver, quartermaster of Techport, is involved in this and is looking at the possibilities of how this can possibly be integrated. In time, they will also look at whether other ROCs and VO-schools might be able to join so that Smart mainetenance becomes available to more students.

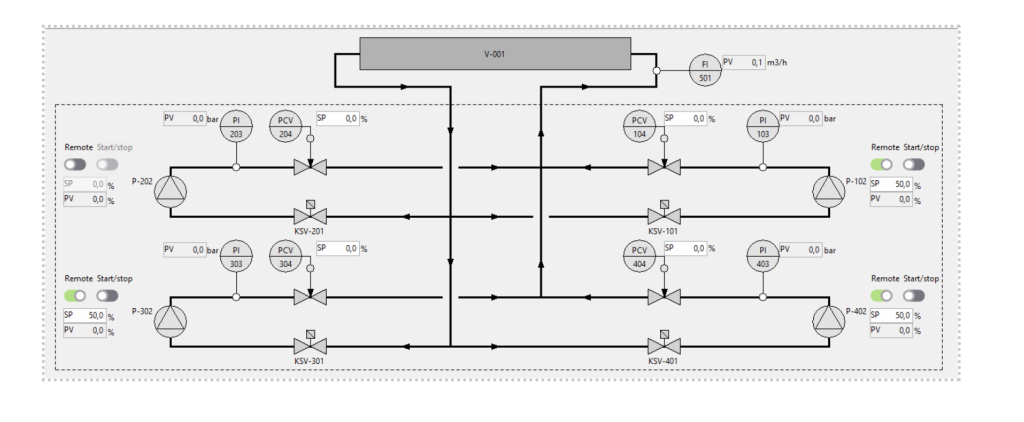

How exactly does the installation work?

Through sensors on the pilot plant, various observations can be made. For example, consider trends from vibration meters. Based on the data, it can be concluded when a bearing is getting worse. As a result, machines do not have to be replaced right away in advance. It can also be concluded that certain things do not run as well as they should, resulting in energy loss, for example. By mapping this, you can reduce energy consumption.

New and sustainable way of working for tech companies

Daisy: "This new technology also plays a big role in sustainability by saving energy and resources. In addition, it provides students with knowledge for the future. Many companies do not yet have the new technology and with the knowledge of these students they can plan their maintenance better and can work in a new and sustainable way."

Want more information? Feel free to contact Daisy. She would be happy to tell you more about this new technology!